High Pressure Pump VG1246080097

1.Superior Pressure Generation:Generates high - intensity pressure efficiently, enabling excellent performance in demanding applications.

2.Exceptional Durability:Built with top - grade materials, it withstands harsh conditions, ensuring long - lasting service life

3.Precise Pressure Control:Offers accurate pressure regulation, contributing to stable and reliable system operation.

4.Optimal Compatibility:Specifically designed for targeted systems, ensuring seamless integration and maximum efficiency.

High Pressure Pump VG1246080097: A Comprehensive Introduction

1. General Overview

2. Design and Construction

2.1 Materials

Body: The pump body is crafted from high - strength, corrosion - resistant materials. Typically, it is made of alloy steels that offer a perfect balance between durability and weight. These alloys are chosen for their ability to withstand high internal pressures, which can reach extreme levels during operation. The use of such materials also safeguards the pump against the corrosive effects of various fluids, extending its service life significantly.

Internal Components: The internal components, such as pistons, valves, and seals, are manufactured from specialized materials. Pistons are often made of hardened metals to endure the repetitive high - pressure forces. Valves are constructed from precision - machined materials that can open and close rapidly and accurately under high - pressure conditions. Seals, on the other hand, are made of high - performance elastomers or advanced composite materials. These seals are designed to prevent fluid leakage, maintaining the integrity of the high - pressure system.

2.2 Precision Engineering

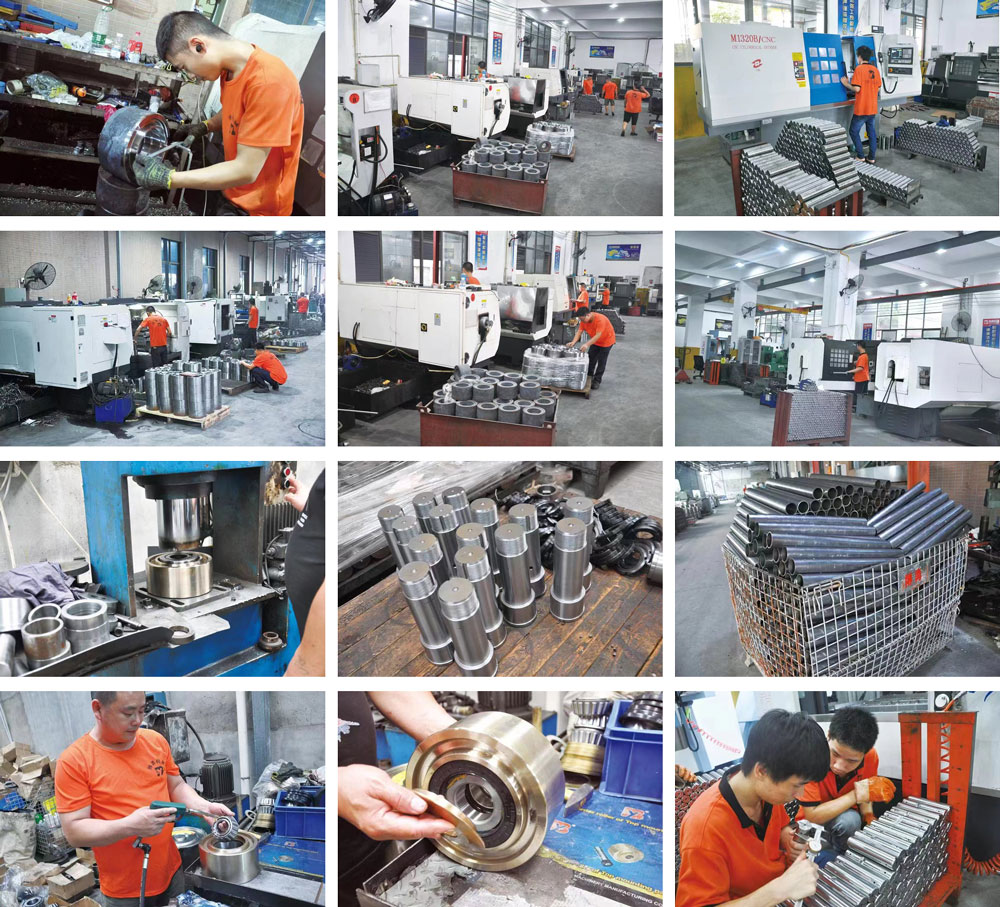

Manufacturing Tolerances: The manufacturing process of the VG1246080097 high - pressure pump adheres to extremely tight tolerances. Every component is machined to within micrometer - level accuracy. This precision ensures that all parts fit together perfectly, minimizing internal clearances that could otherwise lead to energy losses, leaks, or premature wear. For example, the piston - cylinder fit is designed to be so precise that it allows for smooth reciprocating motion while maintaining the necessary pressure differential.

Flow Path Design: The flow path within the pump is carefully engineered. It is designed to minimize turbulence and pressure drops as the fluid passes through the pump. The inlet and outlet ports are shaped and positioned to optimize the flow of fluid in and out of the pump, ensuring efficient operation. The internal channels are also polished to reduce friction, further enhancing the pump's performance.

3. Functionality

3.1 Pressure Generation

Principle of Operation: The High Pressure Pump VG1246080097 operates on a reciprocating or rotary principle, depending on its specific design. In a reciprocating design, pistons move back and forth within cylinders. As the piston retracts, it creates a vacuum in the cylinder, drawing fluid into the pump through the inlet valve. When the piston moves forward, it compresses the fluid, forcing it out through the outlet valve at high pressure. In a rotary design, gears or vanes rotate within a housing, trapping and displacing fluid, generating high pressure in the process.

Pressure Range: This pump is capable of generating extremely high pressures. It can typically achieve pressures ranging from [lower pressure limit] to [higher pressure limit], making it suitable for a wide range of applications that require intense fluid pressure, such as in high - pressure cleaning systems, hydraulic power units, and certain industrial manufacturing processes.

3.2 Flow Control

Variable Flow Options: Some models of the VG1246080097 high - pressure pump come with variable flow control features. This allows for the adjustment of the fluid flow rate while maintaining the required high pressure. Flow control can be achieved through mechanisms such as variable - displacement pistons or electronically controlled valves. This flexibility is highly beneficial in applications where the flow rate needs to be adjusted according to the specific requirements of the process, such as in spray - painting operations where different spray patterns and flow rates are needed for different surfaces.

4. Applications

4.1 Industrial Applications

Hydraulic Systems: In industrial hydraulic systems, the High Pressure Pump VG1246080097 is used to power hydraulic machinery such as presses, cranes, and forklifts. The high - pressure fluid generated by the pump enables these machines to lift heavy loads, perform precise movements, and exert high forces.

Manufacturing Processes: It is also utilized in manufacturing processes such as injection molding, where high - pressure fluid is needed to inject molten plastic into molds. The consistent and high - pressure flow provided by the pump ensures the accurate formation of plastic parts with high quality.

4.2 Mobile Applications

Construction Equipment: Construction equipment like concrete pumps and hydraulic excavators rely on the VG1246080097 high - pressure pump. The pump supplies the necessary high - pressure hydraulic fluid to operate the machinery's various functions, such as extending the boom of a concrete pump or powering the digging arm of an excavator.

Agricultural Machinery: In agricultural machinery, high - pressure pumps are used for tasks such as spraying pesticides and fertilizers. The VG1246080097 pump can generate the high pressures required to ensure even distribution of these substances over large areas of farmland.

5. Maintenance and Serviceability

5.1 Maintenance Requirements

Regular Inspections: Regular inspections are essential to ensure the continued optimal performance of the High Pressure Pump VG1246080097. Inspections should include checking for leaks, monitoring the pressure and flow rates, and inspecting the condition of the internal components. Visual inspections of the pump body for signs of corrosion or damage should also be carried out.

Lubrication and Fluid Replacement: Proper lubrication of moving parts is crucial. The pump's lubrication system should be regularly checked, and the lubricating oil should be replaced at recommended intervals. Additionally, the fluid being pumped should be monitored for contamination, and it should be replaced or filtered as needed to prevent damage to the pump's internal components.

5.2 Serviceability

Accessibility: The design of the VG1246080097 high - pressure pump takes into account serviceability. Key components are designed to be easily accessible for maintenance and repair. For example, the pump's end - caps can be removed without excessive disassembly, allowing for quick inspection and replacement of internal parts such as pistons and valves.

Availability of Spare Parts: A comprehensive range of spare parts is available for the VG1246080097 pump. This ensures that in the event of component failure, the pump can be quickly restored to its optimal working condition. The availability of spare parts also contributes to the long - term cost - effectiveness of using this pump, as it reduces downtime and the need for costly replacements.

6. Quality Assurance

6.1 Manufacturing Standards

Compliance with Regulations: The production of the High Pressure Pump VG1246080097 adheres to strict international and industry - specific manufacturing standards. It complies with regulations such as ISO standards for quality management systems, ensuring that the pump is manufactured to the highest quality levels. These standards cover all aspects of the manufacturing process, from raw material sourcing to final product testing.

Quality Control Measures: Stringent quality control measures are implemented throughout the manufacturing process. Each component is inspected at multiple stages, and the final assembled pump undergoes comprehensive testing. This includes pressure testing to ensure that the pump can withstand the rated pressures without leakage, performance testing to verify that it meets the specified flow and pressure requirements, and durability testing to simulate long - term operation.

6.2 After - Sales Support

Technical Support: In addition to manufacturing a high - quality product, the manufacturer provides extensive technical support. This includes assistance with installation, troubleshooting, and maintenance. Technical experts are available to answer customer queries and provide guidance on optimizing the pump's performance.

Warranty: The VG1246080097 high - pressure pump is typically backed by a warranty. The warranty period reflects the manufacturer's confidence in the product's quality and durability. During the warranty period, if the pump fails due to manufacturing defects, the manufacturer will repair or replace the pump at no cost to the customer, providing peace of mind to users.

Basic Info.

VG1246080097 Sinotruk Spare Parts high pressure pump | |||

Type: | high pressure pump | Application: | Sinotruk |

Truck model: | Certification: | ISO9001 | |

OEM number: | VG1246080097 | Warranty: | 6 months |

Item Name: | high pressure pump | Packing: | standard |

Place of origin: | shandong, China | MOQ: | 1 Piece |

Brand name: | sinotruk | Qulity: | OEM original |

Adaptable automobile mode: | SINOTRUK | Payment: | TT, western union, L/C |

1).Be promptly to reply each inquiry within 12 hours;

2).Quality controlled in the factory from sample to mass production;

3).Keep on service until the goods arrive to customers;

5).You can contact me anytime , while you have question and demands.

FAQ:

Q1. What is your terms of packing?

A: Generally, we pack our goods in Carton boxes and then in wooden case.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages

before you pay the balance.

Q3. How about your delivery time?

A: Generally, it will take 7 to 30 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q4. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.